Product Testing

All Blue Diamond® products are subject to the following applicable tests where appropriate, conducted by independent laboratories prior to their introduction to the market:

ASTM D3574 - Test H Ball Drop

Measures the rebound height the ball travels after impact to the mat; the higher the bounce the greater the rebound of the material. A low rebound in a floor mat would be a sustained foot imprint of the mat after a person walks off of the mat.

ASTM D3574 - Compression/Deflection

This test assesses the anti-fatigue properties of floor mats. This measures the force per sq. inch after compressing the material by a percentage normally 25 or 65%. The position is held for 60 seconds and then measured. This is a comparative measure to tell how supportive the floor mat is; meaning when you step on the mat does it bottom out with no push back or does it feel supportive beneath your feet.

ASTM D1894 - Static Coefficient of Friction

This measures the force to slide a weighted object resting on the sample. The coefficient is calculated by dividing the force to slide by the weight of the object. (If the object weighs 50 lbs. and it takes 40 lbs. to slide it horizontally the COF is .80)

ASTM D2240 – Durometer

A tool that penetrates from the top surface to measure the hardness. There is no real life correlation it is based on the calibrated Durometer.

ASTM D2859/DOC FF1-70 (PillTest) – Flammability

Federally required flame test for all flooring materials via the CPSC. Uses a small pill that ignites for 3 minutes, the flooring must self-extinguish.

D1004 - Tear Strength

The force to rip a material that has been started to tear. Can be done as received and after aging cycles.

ASTM D412 - Elongation/Tensile Strength

The tensile strength is the pound per sq. inch required to break a material in half by pulling a 25.4mm strip from opposite ends. The amount it stretches before breaking is the elongation.

ASTM E648 - Critical Radiant Flux

Test for commercial flooring that measures the amount of energy/heat required to keep a material on fire. Commercial fires produce heat and materials tend to burn more readily with heat. The higher the energy required to keep something burning the more flame resistant the material is.

ASTM D6540 - Accelerated Soiling Test

Designed to simulate the soiling that occurs from foot traffic during normal use.

Accelerated Wear Test (S.I.M. Floor Machine)

Designed to simulate the wear an entrance mat will receive under normal foot traffic. The results show the relative wear and crush resistance of the mat.

Water Retention

Designed to simulate the moisture retention of an entrance mat.

ASTM D3884-92 - Abrasion Resistance

This is an accelerated wear test with results measured in weight loss.

AATCC Test Method 147 – Antibacterial Assessment of Textile Materials

The objective is to detect bacteriostatic activity on textile materials.

ASTM E2149 – Antimicrobial Activity

This test method is designed to evaluate the antimicrobial activity of non-leaching, antimicrobial-treated specimens under dynamic contact conditions.

ASTM G22-76 - Bacterial Resistance

Designed to evaluate bacterial activity in plastic materials.

ASTM G21 - Fungal Resistance

Standard practice for determining resistance of synthetic polymeric materials to fungi.

Glossary of Terms

A listing of commonly used terms and phrases found throughout this website:

ANTI-FATIGUE: Cushioning qualities that alleviates foot pressure, stimulates blood circulation and helps reduce stress on the neck, legs, and lower back.

CHEMICAL RESISTANCE: The degree to which industrial matting products can withstand the erosive qualities of chemicals found in applicable environments.

DENIER: Denier is defined as the thickness of the yarn strand. Combined with the face-weight (grams of yarn per square metre), and the density or volume of yarn strands. It is a critical factor in the performance, quality and durability of an entrance mat.

DYNA-SHIELD®: A process that creates a tough protective barrier on the surface of foam anti-fatigue mats. Dyna-Shield® products are more resistant to wear than traditional sponge matting.

MICROSTOP™: A unique anti-microbial rubber compound made from a specially formulated blend of raw materials that inhibits the growth of micro-organisms such as bacteria and fungi that can cause odour, stains and product deterioration.

NEEDLEPUNCH: A manufacturing process for carpet matting, needlepunch is engineered with a unique blend of 4 Denier thicknesses of polypropylene yarn ranging from very fine to very thick. Needlepunch products are typically more durable, offering better crush resistance and wearability due to the density of the yarn used in the process.

NITRILE RUBBER: A synthetic rubber specifically designed for harsh environments providing superior oil, grease, animal fat, and chemical resistance, abrasion resistance, gas permeability, and thermal stability.

PVC COMPOUNDS: PVC (Polyvinyl Chloride) is a plastic compound used in a variety of manufacturing processes and end products. PVC is known for its durability, resistance to moisture, versatility, and its ability to withstand harsh environments.

TUFTED: An alternative process to needlepunch for manufacturing carpet matting, tufted products are sewn into a backing using a finer yarn. Tufted mats generally are less dense and offer better moisture retention.

UNIFUSION™: A revolutionary bonding technology that uses heat and pressure to fuse a floor matting top surface to a base material. The resulting finished product is virtually a single piece, thereby eliminating the possibility of de-lamination.

ANTIMICROBIAL: Destructive to or inhibiting the growth or pathogenic action of microorganisms.

ANTIBACTERIAL: Destructive to or inhibiting the growth of bacteria.

PATHOGENIC: Capable of producing disease

GRAM POSITIVE/GRAM NEGATIVE BACTERIA: Gram positive and gram negative refers to how a bacterium reacts to a gram stain. The difference is the outer casing of the bacteria. A gram-positive bacterium will have a thick layer of peptidoglycan (a polymer made up of amino acids and sugars) that the stain can penetrate. A gram-negative bacterium has an outer membrane covering a thin layer of peptidoglycan on the outside. The outer membrane prevents the initial stain from penetrating. This outer membrane also gives the bacteria a greater degree of protection therefore making it more resistant.

The Science of Anti-Fatigue Matting

How an anti-fatigue mat works is well described in an article that was published in the April 1999 issue of “Occupational Health & Safety”, written by James M. Kendrick:

“Anti-fatigue mats are engineered to make the body naturally and imperceptibly sway, which encourages subtle movement by calf and leg muscles. This promotes blood flow and keeps it from stagnating in the veins, which causes workers to feel fatigued.” Standing on hard surfaces for long periods can lead to several problems. First, standing causes muscles to constrict, which reduces the blood flow. This makes muscles and joints hurt, and it causes blood to stagnate. In addition, long-term standing causes pronation, or excessive flattening of the foot. While this can be simply tiring and a bit painful, it can also lead to plantar fasciitis and other serious foot conditions. Lower back pain is highest in workers who stand 4 hours or more per day.

As noted by Mr. Kendrick, the cushioning effect of anti-fatigue matting allows continuous micro-movements of the feet, which minimizes blood pooling in the legs. Too much cushioning can have a negative effect. Too great an amount of softness or “give” will actually cause excessive fatigue because it overworks the muscles. Think of it like jogging on the beach as an extreme example of this concept.

Standing at Work

In many industries, employees are required to work while standing, walking and/or carrying loads. Lower extremity discomfort and fatigue from forced long term standing and walking is a problem often identified, but seldom documented. Early studies such as Morgora (1972) showed that the incidence of low back pain was highest in those workers who stood regularly every working day for periods of more than four hours and Bousseman et al. (1982) brought to light that long term standing is a direct cause of pain and discomfort.

Subsequent research carried by Dr. Mark Redfern and Dr. Don Chaffin at the Center for Ergonomics, University of Michigan in 1988, and Paula Hinnen and Stephan Konz at the Department of Industrial Engineering, Kansas State University, 1994, made observations of the difference between standing on hard floors versus standing on soft floors. Both their studies concluded that mats significantly affect fatigue and comfort in different body regions.

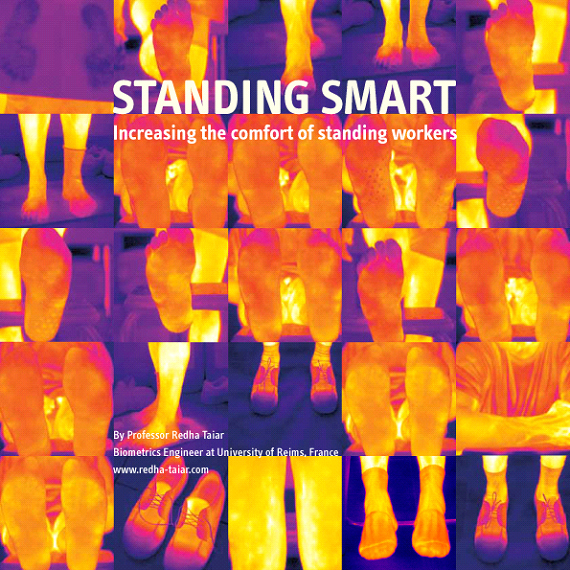

New Research

A recent study conducted by Prof. Dr. Redha Taiar (2011) an expert in biomechanical, human locomotion, kinematic and kinetic analysis and biomedical technologies at the University of Reims in France showed how human mechanics in a working environment are impacted through the use of anti-fatigue mats.

Studying the upright position of the human body, the adjusting of its segments to maintain its balance and diminishing muscular problems are the main elements to highlight in order to improve the everyday (working) life of users.

By observing workers and measuring foot pressure for employees standing for long periods, Prof. Taiar was able to identify two causes of fatigue and therefore a two-pronged approach in combating the muscular-skeletal disorders associated with long-term standing.

Professor Redha Taiar of the University of ReimsOne cause of fatigue: the Cinderella Fibres

The consequences of long term standing on a muscular-skeletal level begin with training muscles. For the human body to remain in an upright position, namely standing, we have trained our muscles in what becomes an automatic system. Basically this posture state (upright) is engrained in our neuromuscular program, and each time we use the same muscles to do the work, without us being conscience about this. This ‘automated’ muscular functioning is recorded in the brain and will be systematically applied.

The muscular fibres involved in this programming are also called « Cinderella fibres », because even if they are tired they do their job …that’s the start of muscular-skeletal troubles (pain, contractures, tendinitis…).

Another cause of fatigue: imbalance

In addition to overuse of the same muscles, when the system is out of balance, the muscles must work harder to search for balance and the quick reaction speed is maintained at the cost of energy (fatigue).

So to maintain an upright position it is necessary to have a well-adapted postural balance to decrease pathologies and their consequences in the everyday work of the users. In a nutshell, to regain balance ‘quick reaction /energy saving/ effectiveness’ it is necessary to become aware of the different foot pressures on the ground and the most proper muscle action (from head to toe).Professor Redha Taiar study on Anti-Fatigue Matting

Conclusion: Without a mat, there is an imbalance

He emphasized that “without a mat there is a dysfunction in the balance of a person which can cause pathologies that are accelerated by a repetitive task and other constraining work”. Such unbalance is very harmful for the human body. The use of anti-fatigue mats enables correct balancing and a uniform distribution between the right and left leg. Prof. Taiar’s findings confirmed that pains are substantially reduced with the use of anti-fatigue mats compared to the initial situation without mats.

Two-part solution to fight fatigue

Taiar therefore recommends a two-part approach in reducing fatigue. Firstly, the worker must initiate a variation in foot pressure to improve the upright standing position. This top down approach helps to eliminate the build-up of pressure points on the feet (Cinderella fibres). To achieve this, his advice to workers is to regularly change the pressure point inside the shoe. Secondly, by using anti-fatigue mats made from the latest technological materials. This bottom up approach helps to eliminate pressure points from the floor by spreading weight evenly. The use of anti-fatigue mats correct balance and restore uniform distribution between the right and left leg. The unique composition of anti-fatigue matting is an ergonomic pattern and a cushioning underlay which evenly distributes weight and stimulates continuous micro-movements of the feet minimizing blood pooling in the legs. Prof. Taiar’s findings confirmed that pains are substantially reduced with the use of anti-fatigue mats compared to the initial situation without mats.

Workers agree

Feedback from employees was also used to support the research using observations from workers who compared working on anti-fatigue mats to working on the hard floor and noting their level of comfort and fatigue every hour during eight-hour shifts. One worker commented: “Less fatigue in the legs at the end of the day and less muscular and articular troubles, better absorption of weight.”

The ROI of Anti-Fatigue Matting

Installing anti-fatigue and safety matting is an investment in people. There is also good reason to believe that reduction of fatigue also reduces the occurence of accidents and improves general work efficiency. This may also go hand-in-hand with the desire to reduce slips and falls. There are fewer days lost to injuries, fewer medical claims, and compliance with new health and safety requirements.

Blue Diamond® floor mats are made of specific formulations and designs that provide fatigue relief which will contribute to increased productivity and employee satisfaction.