When it comes to selecting the right material for your structural project, the choice between Glass Reinforced Polyester (GRP) grating and Steel grating is critical. While both materials have their merits, we're here to highlight the compelling advantages of choosing GRP over Steel.

In this blog, we'll delve into five key factors: Strength vs. Durability, Corrosion Resistance, Weight and Installation, Cost Considerations and Anti-Slip Protection, explaining why GRP should be your material of choice.

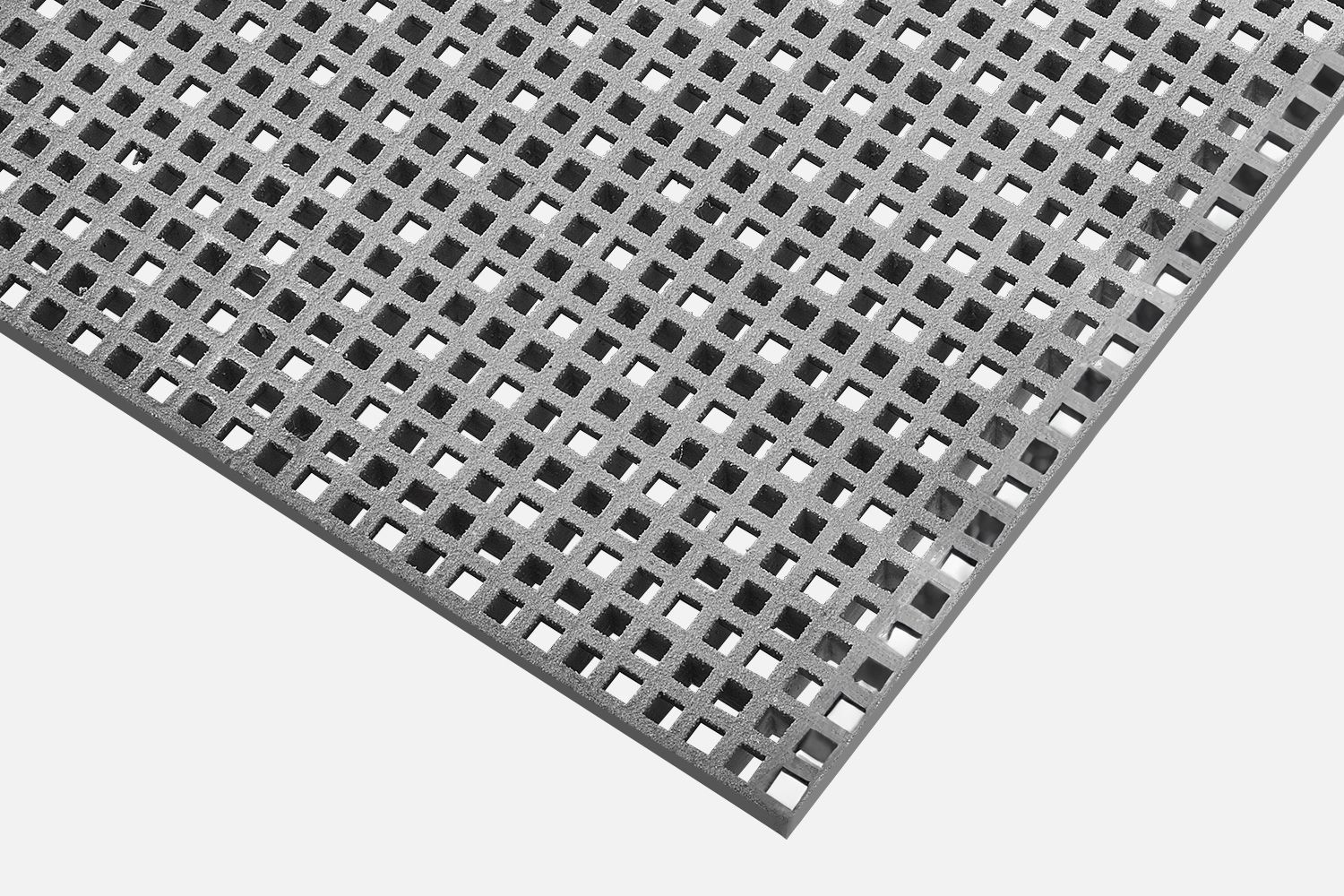

- Strength vs. Durability: While Steel grating boasts impressive strength, perfect for heavy-duty applications, GRP excels in durability, offering a maintenance free solution with a far higher strength to weight ratio than steel. GRP grating's resilience can outlast the brute strength of steel, ensuring your project stands the test of time. In choosing GRP over steel, you're investing in a material that not only meets but exceeds your strength requirements, ensuring that your project will remain durable for years to come.

- Corrosion Resistance: One of the standout features of GRP is its remarkable resistance to corrosion. In environments where steel might falter, GRP thrives. Imagine a project near the coast, where saltwater corrosion is a constant threat, GRP grating remains unaffected, while steel would quickly degrade. Opting for GRP is the prudent choice when you need a material that can withstand harsh conditions, or for any project exposed to corrosive elements.

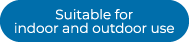

- Weight and Installation: GRP is up to 75% lighter than steel which offers significant advantages such as reduced transportation costs, simplified installation, and a decrease in overall project complexity. By choosing GRP, you not only save on costs but also streamline your project's implementation, ensuring it is completed efficiently and with ease.

- Cost Considerations: While steel may have a lower initial investment cost, GRP excels in terms of overall cost-effectiveness. With GRP, you benefit from reduced maintenance, an extended lifespan, and potential savings over the life of your project.

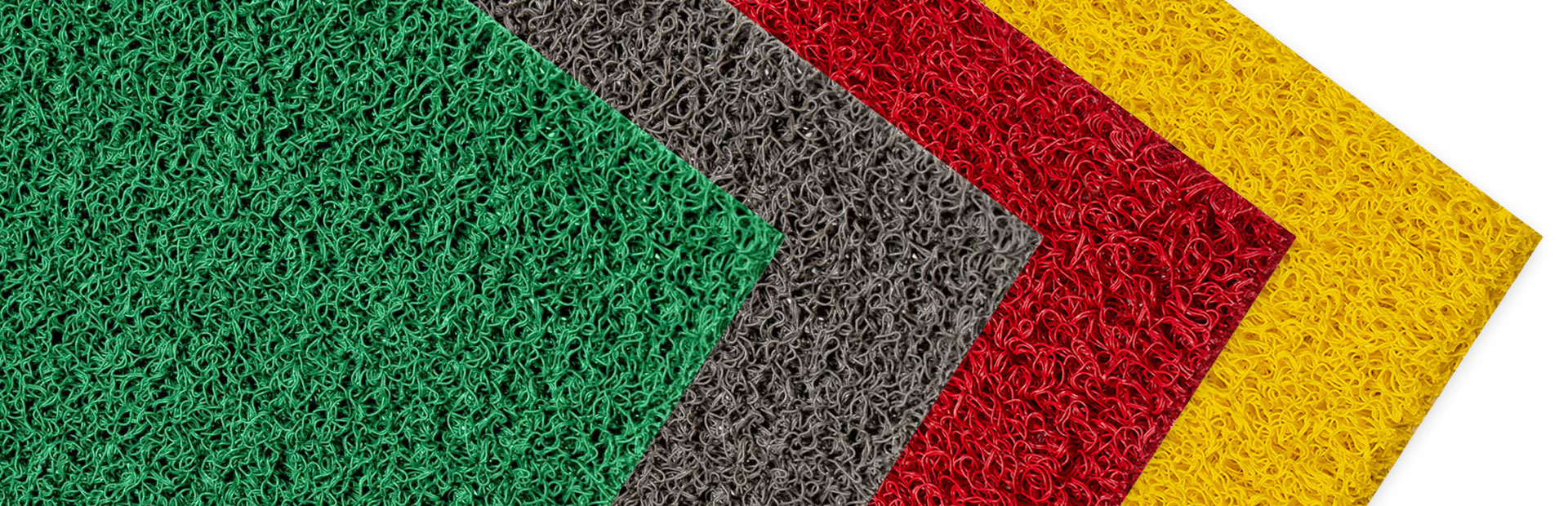

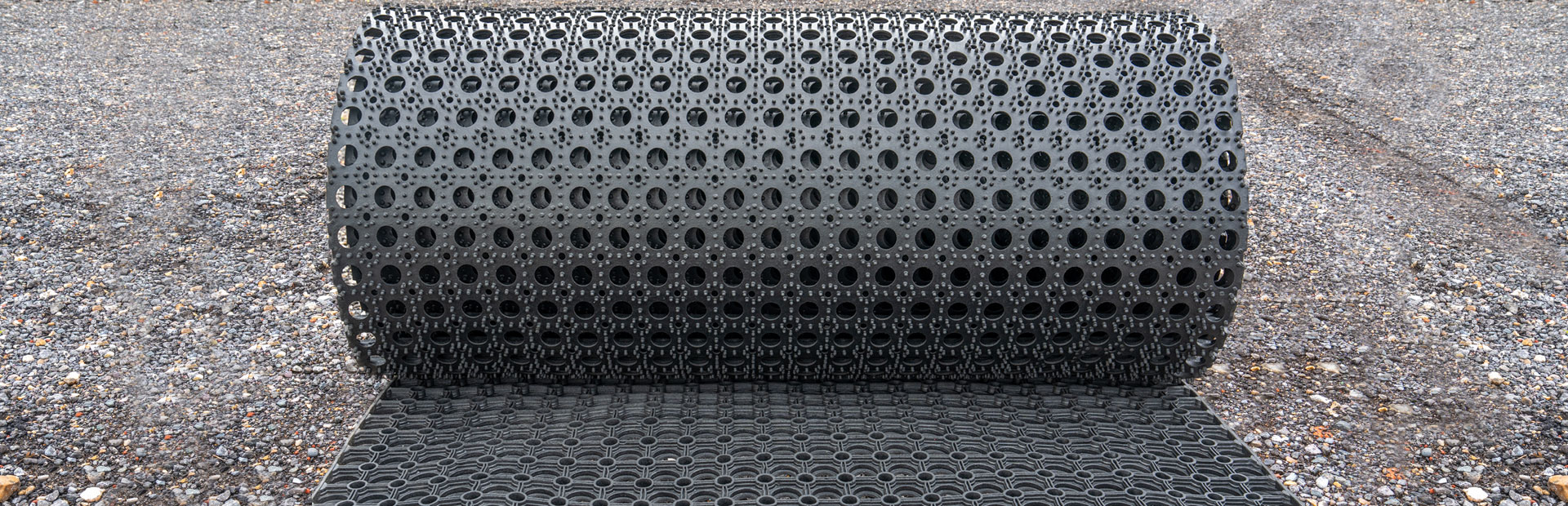

- Anti-Slip Protection: GRP can be manufactured with a variety of different finishes. One of the most popular is the anti-slip surface, which provides grip and stability, even when wet. Unlike steel, which can become hazardous when wet, GRP remains a safe and secure product to use in any wet, oily, or damp conditions.

GRP is a very versatile material and is the perfect solution for platforms, walkways, flooring, risers, ramps and covers for industrial and construction sites, chemical and shipping industries, water treatment plants as well as offshore oil rigs. With our in-house cutting team, we can also provide grating cut to specific sizes, ensuring a perfect fit for your project.

Why not get in touch to discuss your project needs and the benefits of GRP.