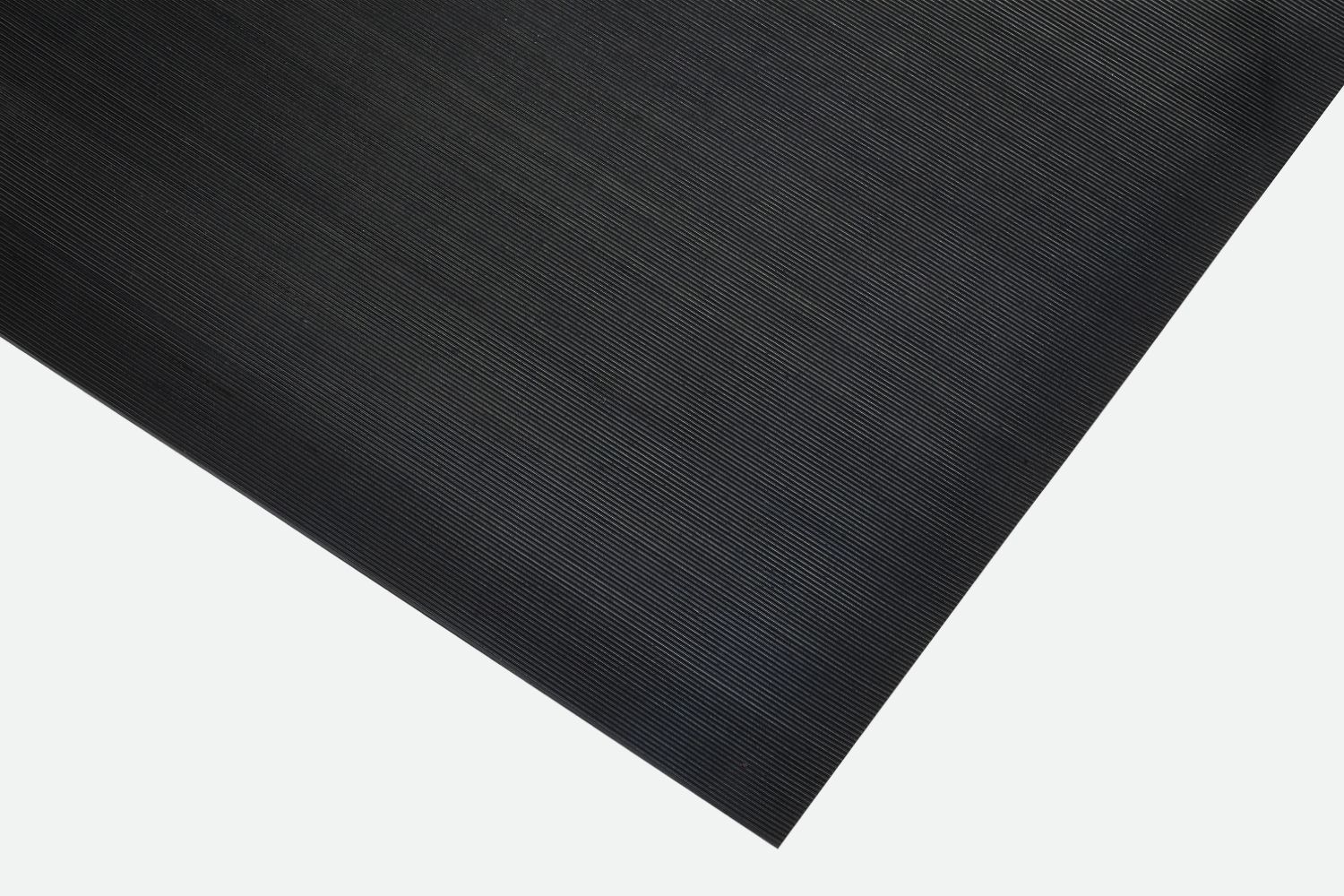

Electrical Safety Matting, also known as Electrical Insulating Matting, is a specialist rubber matting material designed to protect against electrical shocks. It is crucial in environments where electrical equipment is handled or maintained, acting as a barrier between individuals and potentially hazardous electrical surfaces.

Classes of Electrical Safety Matting

There are various classes of Electrical Safety Matting, each offering different levels of voltage protection. Selecting the appropriate class is essential for the safety and protection of your workforce.

Class 0

- Maximum working voltage: 1,000 volts (1KV)

- Proof test voltage: 5,000 volts (5KV)

Class 1

- Maximum working voltage: 7,500 volts (7.5KV)

- Proof test voltage: 10,000 volts (10KV)

Class 2

- Maximum working voltage: 17,000 volts (17KV)

- Proof test voltage: 20,000 volts (20KV)

Class 3

- Maximum working voltage: 26,500 volts (26.5KV)

- Proof test voltage: 30,000 volts (30KV)

Class 4

- Maximum working voltage: 36,000 volts (36KV)

- Proof test voltage: 40,000 volts (40KV)

Lower voltage

- Working voltages 450V and 650V

- Recommended where lower levels of electrical protection are needed

Always ensure that any matting you purchase complies with relevant standards, such as ASTM D178, IEC 61111, or BS EN 61111:2009. These standards cover thickness, working voltage, and other properties for each class.

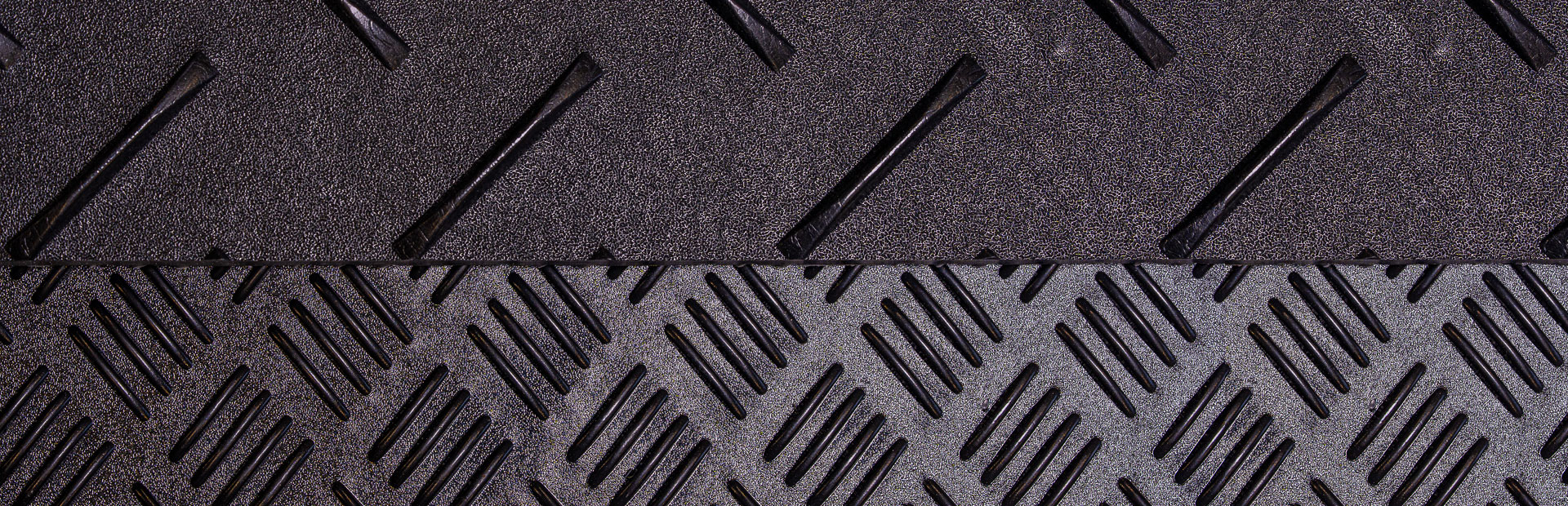

Factors to consider

In addition to voltage ratings, consider factors like durability, chemical resistance, and slip resistance when choosing the right electrical matting. Proper maintenance and regular testing of the matting when in use are also necessary to ensure ongoing safety and performance.

Additional benefits

While its primary function is to protect against electric shocks, Electrical Safety Matting offers additional benefits:

- Compliance: Meets safety standards and regulations, ensuring workplace adherence to necessary guidelines.

- Enhanced productivity: Provides ergonomic support, reducing fatigue for workers who stand for long periods.

Applications

Electrical Safety Matting is very versatile and can be used across many industries where there is a risk of electrical hazards, including:

- Switchboard engineers: Provides essential protection against electric shocks while working with switchboards and control panels.

- Manufacturing: Ensures safety in environments with heavy machinery and equipment that operate on high voltages.

- Construction: Protects workers where temporary electrical setups and power tools are commonly used.

- Power generation and distribution: Safeguards personnel in power plants, substations, and electrical distribution facilities.

- Data centres: Protects technicians managing servers and other electrical equipment in data centre environments.

- Telecommunications: Used in telecom facilities to protect workers handling electrical systems.

- Automotive industry: Provides a safe working environment for technicians working on electric and hybrid vehicles.

- Healthcare facilities: Protects staff in hospitals and clinics where medical equipment operates.

Using Electrical Safety Matting ensures a safe working environment, minimising the risk of electrical accidents and enhancing overall safety standards.

At Blue Diamond, we stock of range of electrical safety matting. If you have any questions or, need advice on what class you should use for your application, please do not hesitate to contact us on 01779 841899 or sales@bluediamond.uk.com.